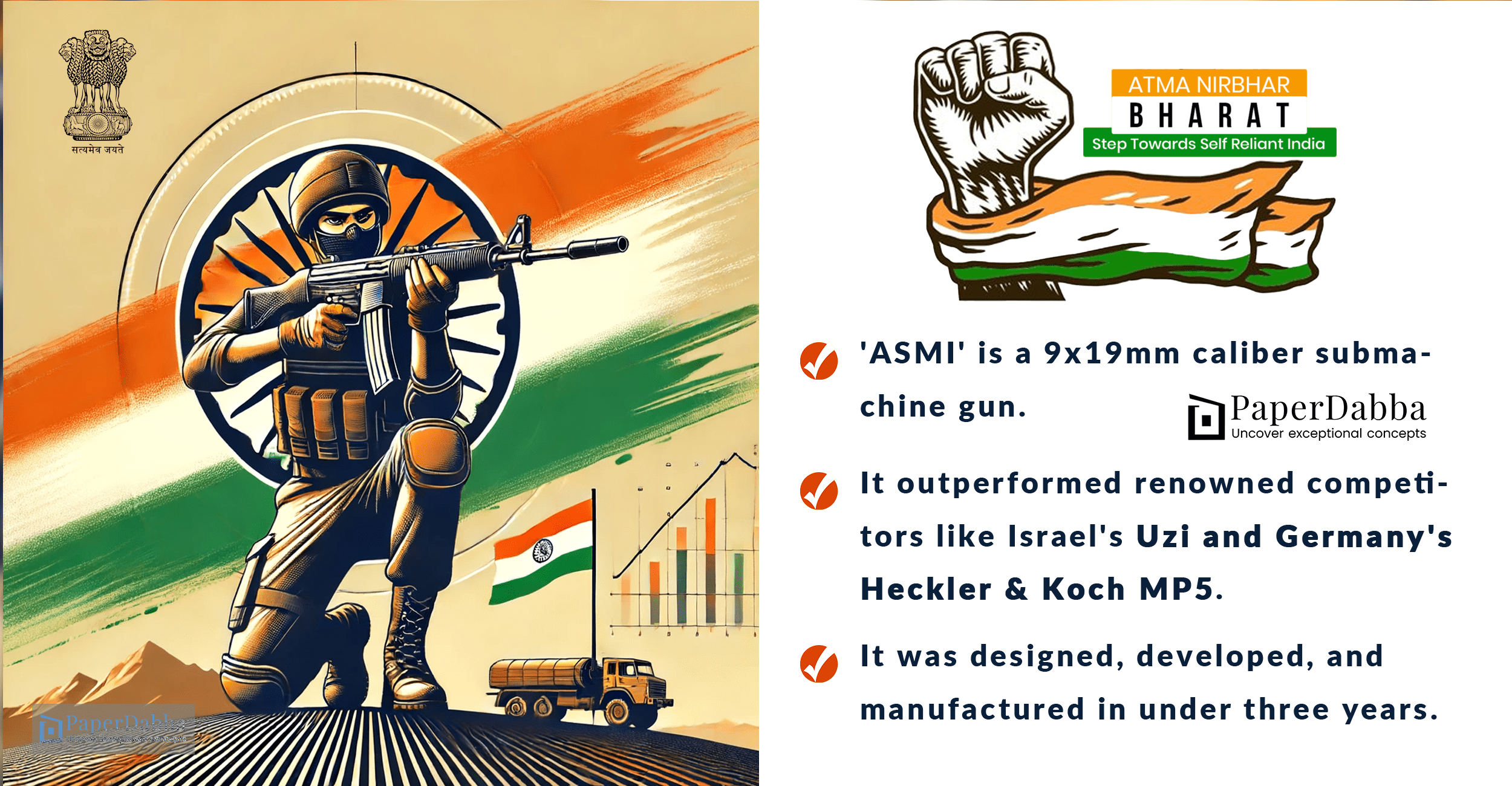

HYDERABAD: In a significant milestone for India’s defence manufacturing sector, Hyderabad-based Lokesh Machines Ltd has secured an order to supply 550 units of its newly developed 9×19 mm calibre submachine gun, ‘ASMI,’ to the Northern Command of the Indian Army. This marks the first time an indigenously designed, developed, and manufactured submachine gun has been inducted into the Army.

Lokesh Machines Ltd, traditionally known for its CNC machines, has ventured into small arms manufacturing with remarkable success. The order, valued at Rs 4.26 crore, underscores the Army’s confidence in ASMI’s capabilities. The submachine gun has also garnered interest from other security forces, including the National Security Guard (NSG), Assam Rifles, and the Border Security Force (BSF).

ASMI’s Competitive Edge

ASMI, which stands for ‘Asmita’ (pride), boasts a design that accommodates both local and NATO-standard imported ammunition. This versatility and its competitive pricing—nearly 30% cheaper than its imported counterparts—make it an attractive option for various security forces.

The submachine gun’s lightweight design, at under 2.4 kg, makes it 10-15% lighter than international models, such as Israel Weapon Industries’ Uzi and Heckler & Koch’s MP5 from Germany. “ASMI was pitted against global competition in terms of accuracy and reliability and outperformed them,” said M. Srinivas, director of Lokesh Machines Ltd.

Atma Nirbhar Bharat Initiative

The success of ASMI can be significantly attributed to the Atma Nirbhar Bharat (Self-Reliant India) initiative launched by the Modi government. This initiative has created a conducive environment for indigenous manufacturing and innovation, enabling Indian companies to compete with global counterparts. The vision of Atma Nirbhar Bharat has substantially bolstered India’s defence manufacturing sector, encouraging companies like Lokesh Machines Ltd to develop advanced weaponry domestically.

Development and Manufacturing

The basic design of ASMI was provided by the Armament Research & Development Establishment (ARDE) in Pune and the Indian Army, which Lokesh Machines Ltd further refined and manufactured at its factory in Toopran, on the outskirts of Hyderabad. The factory has a capacity of producing 12,000 units per annum.

The development process for ASMI took about six months, while the licensing for manufacturing extended the timeline. Despite this, the company achieved a remarkable feat by designing, developing, and manufacturing a weapon within three years, a timeline that rivals global standards for experienced manufacturers.

Rigorous Testing and Reliability

ASMI has undergone extensive testing, including drop, weather, and mud tests, as well as a rigorous reliability test in which it fired 2,400 rounds without a single class-1 stoppage. The weapon’s rate of fire is 800 rounds per minute, and its magazine capacity is 32 rounds.

“It’s a highly accurate weapon, as proven in trials by the Army,” Srinivas noted. “It is also reliable and rugged.”

Future Prospects

The initial order from the Northern Command is set to be fulfilled by September 28. Pilot lots of ASMI have already been delivered to the NSG and Assam Rifles for testing and further induction, with the BSF also placing a pilot order. This widespread interest underscores ASMI’s potential to become a staple in India’s security apparatus.

As the first indigenously developed submachine gun to be adopted by the Indian Army, ASMI represents a significant step forward in India’s journey towards self-reliance in defence manufacturing. With its competitive edge in cost, weight, and reliability, ASMI is poised to substantially impact the global arms market.

The credit for this achievement also goes to the Modi government’s Atma Nirbhar Bharat initiative, which has provided the necessary support and framework for indigenous industries to thrive and succeed globally.